Volumes of landscaping material like dirt, sand, and rocks.

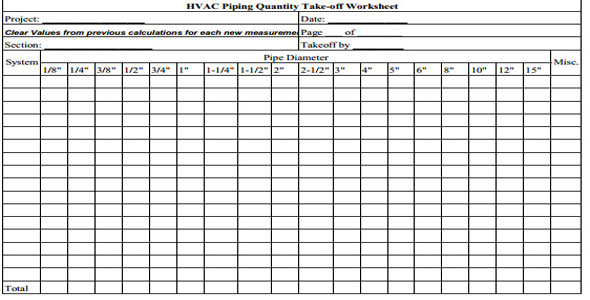

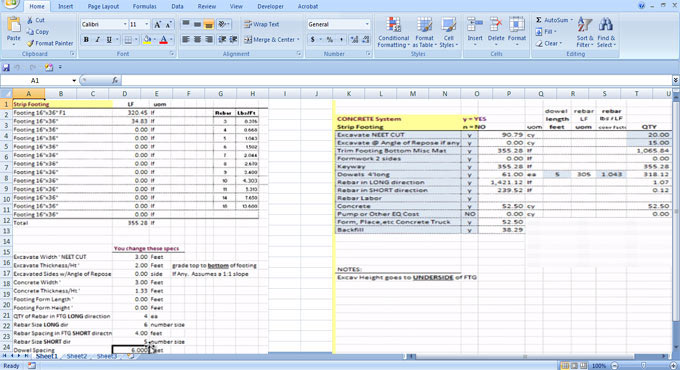

In order to extract these details from the project’s plans and blueprints, contractors must reference the plan’s measurements and annotations and then use those numbers to calculate the different quantities of various supplies and materials. This information about the required materials and supplies is then used to estimate costs used in the project bid. The takeoff process involves contractors and estimators reviewing project blueprints and literally “taking off” or extracting the quantity and material requirements for the project. In construction, takeoff, sometimes called quantity takeoff or material takeoff, refers to the counts and measures of materials and labor required for a construction project. In order to generate accurate estimates, contractors must pull or take off quantity and material information from the project’s blueprints. How can contractors quickly and accurately generate such detailed information from project blueprints? But creating detailed and accurate cost estimates with material requirements is a time-consuming and difficult task. Contractors that confidently understand material and labor costs can create more competitive project proposals and still generate profit on projects. So there is an incentive for contractors to create estimates that are as accurate as possible. For government-sponsored projects, the most competitive bid is required to win the project by law. In the majority of cases, the contractors with the most competitive bids that meet the project’s requirements will earn the work. This detailed cost and scheduling summary is often called a bid, or project proposal. It will include project blueprints and other key information about the project’s location and scheduling requirements. This bid package is sent to a number of contractors or, for government-sponsored projects, posted publicly, and made accessible to any contractor.Īny contractor who would like to work on the project must submit a detailed summary of required materials, labor costs, and schedules to the project sponsor by the bid date. The project owner, which may be a business, state government, or federal agency, will typically compile a group of documents, known as the bid package, which summarizes the project details. This is where the bidding process begins. Once the plans have been finalized, the project owner must find contractors to actually build out the designs, and at a fair price too. Typically, a project sponsor or business owner will work with a team of engineers, architects, and designers to create blueprints for their building or infrastructure project.

The Bidding Processīefore a large construction project ever breaks ground, there is an enormous amount of planning that goes into it. To appreciate all of the intricacies of performing takeoff, it helps to first understand where it fits into the bidding process. Quantity takeoff is just one step of many in the construction project bidding process. Watch Demo Understanding Construction Takeoff

QUANTITY TAKEOFF EXAMPLE SOFTWARE

If you’re already knowledgeable and just want to see the top products, here’s a short list of our picks for the best construction takeoff software (including the best free takeoff software): Lastly, we provide detailed reviews of the best products in the market for each purpose. Starting with an overview of the process, we will then cover all the ways this technology can help and what to look for when comparing software providers. This guide will cover the products that contractors and tradesmen can use to speed up and optimize the takeoff process. Fortunately for the modern contractor, companies have created takeoff software to simplify and improve this process. Traditionally, contractors performed quantity takeoff by hand using printed plans, rulers, calculators, and pencils. However, the process of generating the takeoff data-pulling this detailed information from project plans-can be a very time-consuming process for contractors. That information is then used in cost estimates, project proposals, and supply order forms. Contractors and project managers use blueprints to calculate the quantity and dimensions of materials and supplies needed for the project. States Investing the Most in New HousingĬonstruction takeoff is a necessary step toward estimating costs in a construction project.Cities Investing the Most in New Housing.Construction Project Management Software.Owner Controlled Insurance Programs (OCIP).

0 kommentar(er)

0 kommentar(er)